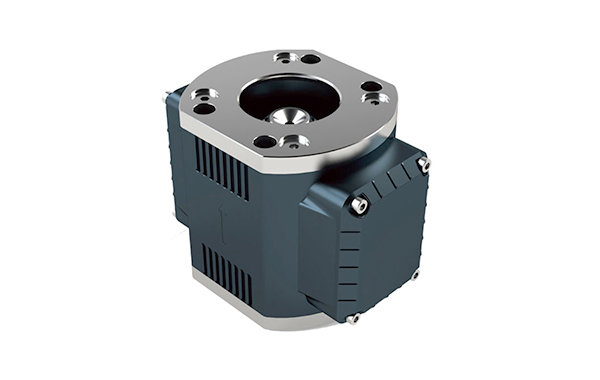

Custom series

Through type wear quantitative sensor

Products based on the principle of electromagnetic induction, the device is designed with a sensitive electromagnetic coil, when magnetic particles pass through the coil, the oil The ferromagnetic particles will change the fixed magnetic field of the sensor, and according to the data changes coupled with the algorithm model of smart matches, the magnetic field changes can be compared with The magnetic particle content establishes a directly readable relationship, and the product is extremely sensitive to abnormal wear particles included in the oil. It can make quick and effective judgment on the equipment wear of large equipment in industrial field, and is suitable for hydraulic oil, gear oil, grease, etc Industrial oil products.

Application field:Steel, petrochemical, shield, power, wind power, large equipment

Applicable oil:Hydraulic oil, turbine oil, diesel oil, gear oil

The product is based on the principle of electromagnetic induction, the device is designed with a sensitive electromagnetic coil, when there are magnetic particles through the coil, oil The ferromagnetic particles will change the magnetic field fixed by the s- ensor. According to the data changes and the intelligent match algorithm model, the magnetic field can be changed The relat- ionship between chemical and magnetic particle content can be directly read. The product is extremely sensitive to abnormal - wear particles inclusions in oil Reaction, can make a quick and effective judgment on the wear of large equipment in the industr- ial field, suitable for hydraulic oil, gear oil, lubrication Grease and other industrial oils.

Application: steel, petrochemical, shield, electric power, wind power, large equipment,

Applicable oil: hydraulic oil, turbine oil, diesel oil, gear oil

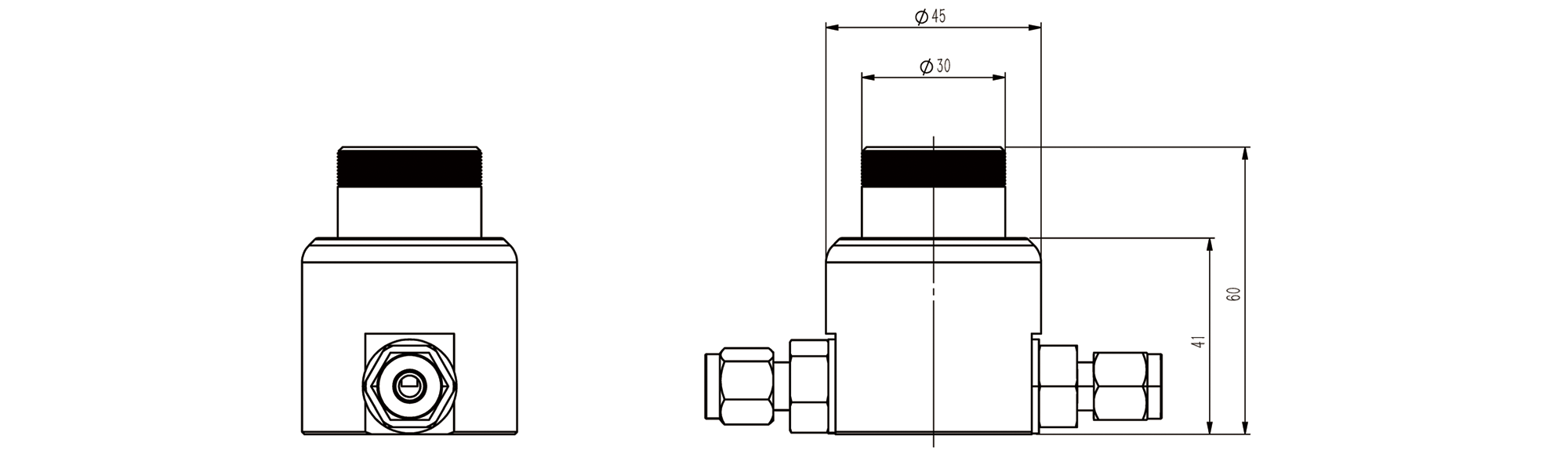

Structure size

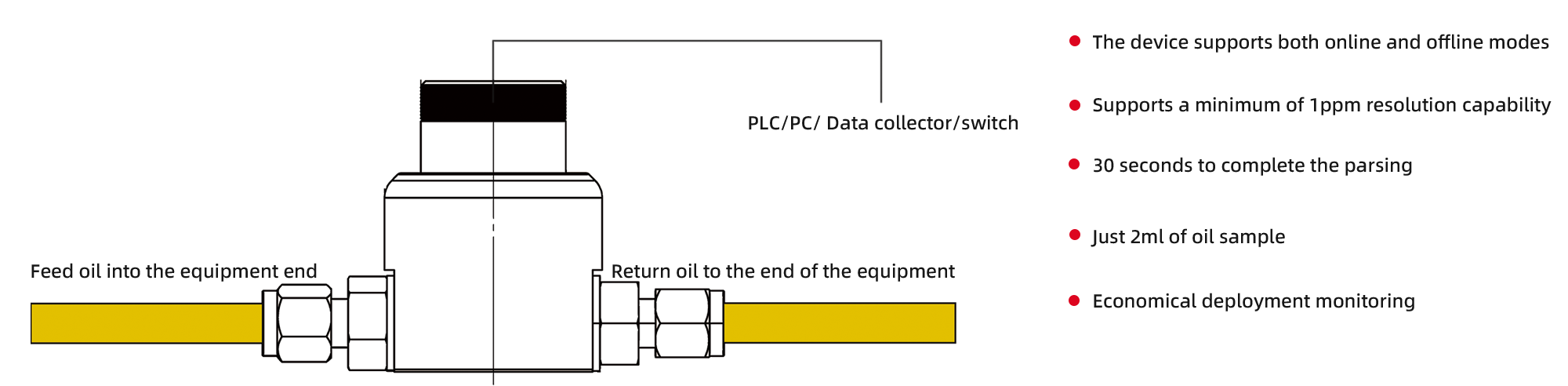

Functional features

Usage mode

Suitable conditions

| Storage temperature | Power source | weight | Operating ambient temperature | Data output | Mode of use | Working environment |

|---|---|---|---|---|---|---|

| -20-50℃ | DC24V | 0.5KG | 10℃-40℃ | RS485 | Online/Offline | non-condensing |

Specificationr

| repeatability | Precision of the screen | Test time | Measurable minimum value | Abrasive particle detection range | Measuring range |

|---|---|---|---|---|---|

| RSD3% | 3PPM | 30 Second | 3PPM | 1um | 0-10000PPM |

Contact us for detailed product parameters