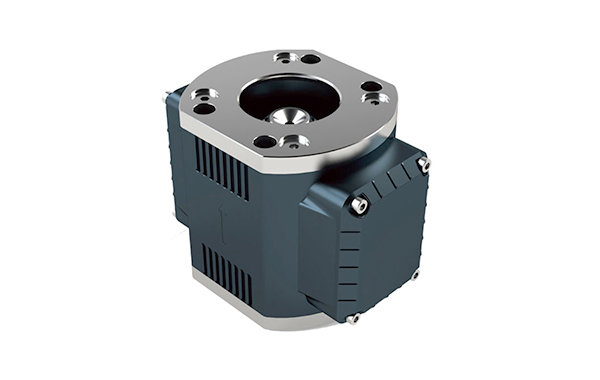

IFM-2series

Non-contact abrasive particle sensor

IFM-2 oil metal abrasive particle sensor is an intelligent sensor specially designed for on-line detection of equipment wear, with its unique micro magnetic induction The measurement technology is extremely sensitive to the changes of ferromagnetic wear particles in oil products, and can continuously and accurately monitor the wear particles in oil products online in real time Content and temperature conditions, products using the latest scientific research technology, the use of new circuit design and model algorithms, fully consider online monitoring The influence of oil viscosity and flow rate on the absorption of abrasive particles on the monitoring is non-contact detection without magnetic suction As long as there are wear particles passing through the oil, the sensor can use a sensitive sensing mechanism to detect the content of the particles through the back end The digital circuit is timely output after transformation, and the maximum possible timely warning of equipment failure to ensure the safety and stability of our equipment Run.

Application field:Steel, petrochemical, shield, power, wind power, large equipment, OEM integration

Applicable oil:Gear oil, diesel oil, insulation oil, etc

Ifm-2 oil metal abrasive sensor is an intelligent sensor specially designed for wear detection of online equipment, with its unique mi- cro magnetic induction The measurement technology is very sensitive to the change of ferromagnetic wear particles in oil produ- cts and can continuously and accurately monitor the wear particles in oil products onlineContent and temperature conditions, p- roducts using the latest scientific research technology, the use of new circuit design and model algorithm, fully consider online mo- nitoring In the process of oil viscosity, flow resistance to abrasive particle adsorption on the impact of monitoring non-contact det- ection method, no magnetic suction As long as there are wear particles in the oil, the sensor can use a sensitive sensing mechanis- m to detect the content of particles, after the back end Digital circuit after conversion, timely output, the maximum possible timel- y warning of equipment failure, to ensure the safety and stability of our equipmentRun.

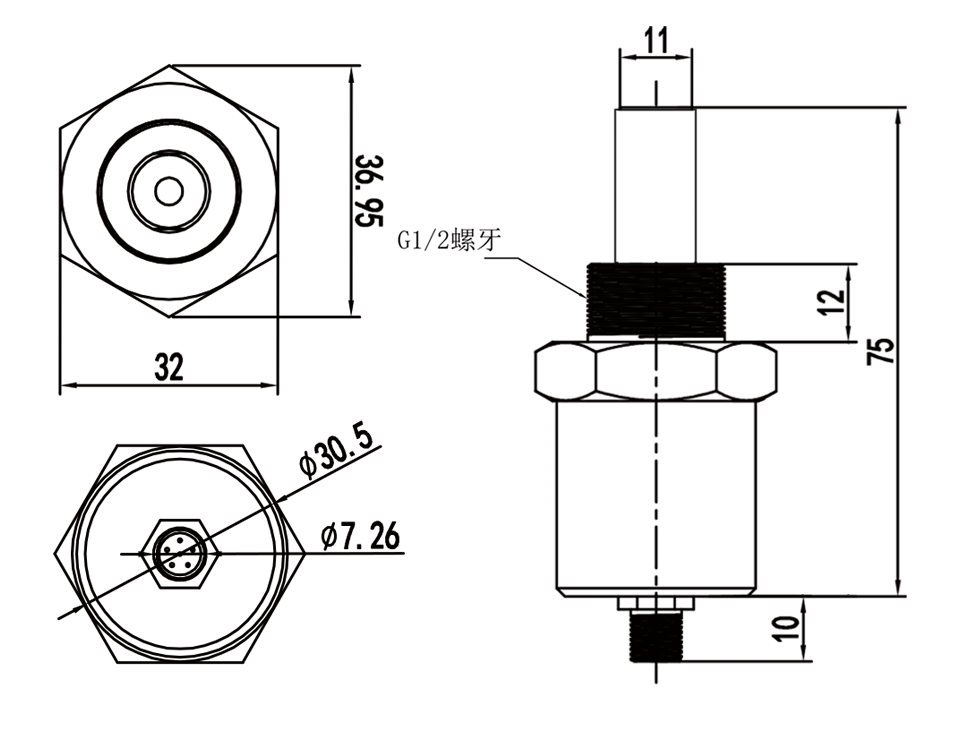

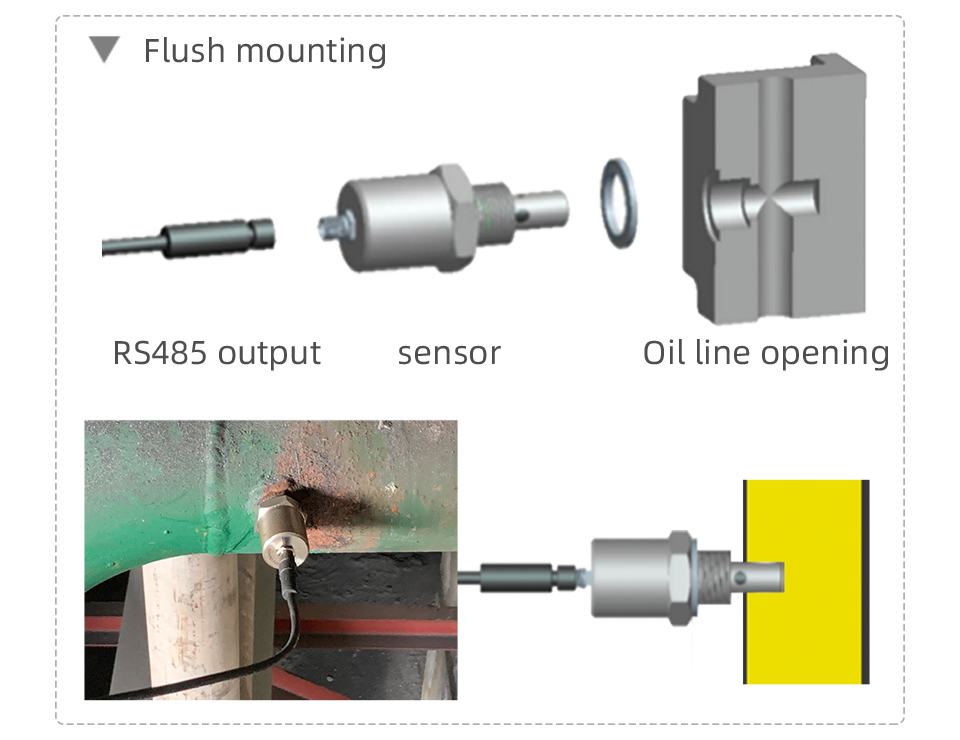

Dimensions and installation

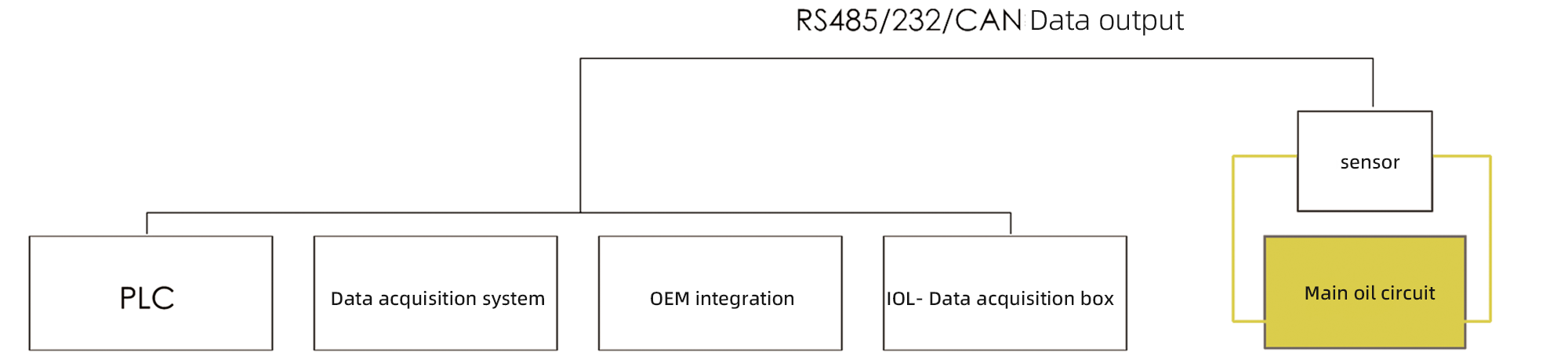

Data transmission mode

Working Condition

| Maximum oil temperature | Oil line pressure | Flow rate of oil circuit | Operating ambient temperature | Highest altitude | Maximum vibration | Maximum humidity |

|---|---|---|---|---|---|---|

| +85℃ | 0-3Mpa | ≤1m/s | -20℃-85℃ | 5000m | 2G | 95% |

Specificationr

| Model selection | Wear particle | Wear index | temperature | Monitoring index |

|---|---|---|---|---|

| IFM-2 | 0-100% | 0-10000ppm | -40~+120℃ | Particle size, wear index, temperature |

| Resolution | 0.1% | 1ppm | ±0.1℃ or ±3% |

The above optional indicators and sensors for any of the models can be configured according to actual requirements.

The accuracy corresponding to the above performance parameters is the typical value of 25℃. In the case of exceeding the requirements of the system working condition, the data may be biased, and the accuracy will change according to the pressure, flow rate, vibration and other data.

Electrical properties

| Communication interface | Data transmission | power | voltage | weight | Shell material | Cable length | Class of protection |

|---|---|---|---|---|---|---|---|

| 6 core jet jack | RS485/232 | ≤2W | DC 9V~36V | 300G | 316L | 1.5m | IP65 |

The above performance indicators are suitable for conventional industrial site installation and use, encounter complex and harsh outdoor environment and fluid property changes, customized design according to site requirements, you can also contact our sales engineers for recommendations